So Monday I finally got everything ready to drop the engine in: engine prepped, engine bay stripped, transmission tunnel hammered out, oil pan swapped, notched engine cross member installed, transmission installed on the engine,etc. The friends I had come over own a well respected local shop called [url=http://fujiispl.com/]Fujii SPL[/url], one of the guys we had here is from Japan and has at dozens of s-chassis engine swaps under his belt, at least 2 of them own swapped S13s.

engine bay cleared out

clutch lines installed and all unnecessary hardware removed

The torque wrench wasn’t working right so we had to use an old-school torque wrench to install the clutch hardware. Also the bolts for the the flywheel that I bought were the wrong size (and I somehow got 2 bags of those) we were also short 2 bell housing bolts… Aggravating. Thankfully the flywheel bolts from the original automatic flywheel worked on the new flywheel and we found some bolts that worked with the bell housing for the time being… placed those on the bottom so they can be swapped out later.

once the transmission was mounted up we set the clutch master in a vice and tested the lines for leaks… I didn’t want to have to pull the whole thing back out of the car to fix the lines if there was a problem. It was kind of ridiculous but it worked well and the lines held up beautifully

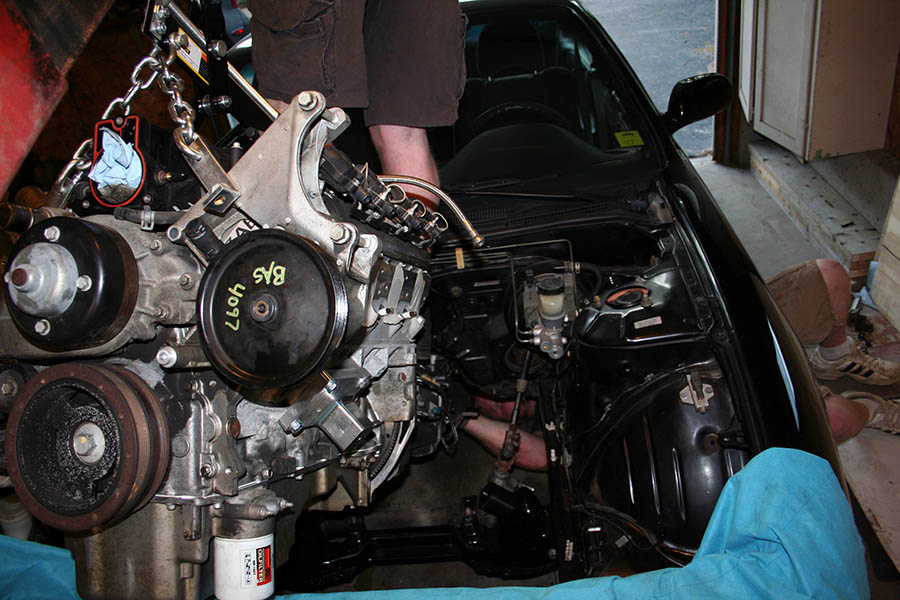

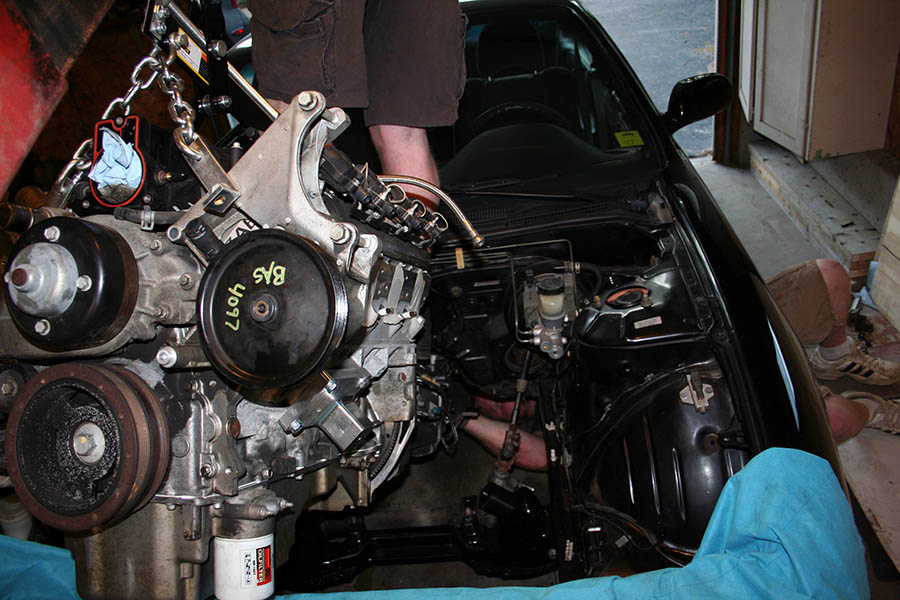

dropping in the engine:

Once the engine was in and we attempted to bold it up we ran into some major fitment issues. It’s sitting in the car right now but we’re going to have to pull it back out to figure out how to get everything to fit. We didn’t have time to test-fit the headers but a quick attempt showed that it wouldn’t be easy and I’m concerned about their fitment as well.

First thing we noticed was that the transmission cross member didn’t fit, we had major alignment issue with it but after we took out the mount and tried to bolt in the cross member alone (without it even touching the transmission) the bolt holes didn’t even line up… with the passenger side bolts lightly threaded in, this is what the driver’s side looked like:

The engine was IN and the mounts were bolted up and sitting flush the trans x-member was only bolted in on one side but sitting flush against the bottom of the car.

…but even still the engine sits slightly towards the passenger’s side, and it’s tilted slightly with the passenger’s side HIGHER than the driver’s side.

Checking the bottom we noticed that there seemed to be plenty of clearance of the driver’s side but the oil pan was actually rubbing on the x-member in 2 spots on the passenger’s side:

Also the hood clearance isn’t happening either: as you can see the hood wont even be close to clearing the throttle body, not to mention the engine is tilted with the front way higher than the rear, which I’m worried will cause issues with the drive shaft.

The alternator isn’t bolted on at the moment but it sits parallel with the throttle body and where it’s off to the side I would imagine there will be clearance issues with that also.

the S14 heater valve was removed before we put the engine in, but attempted to test fit showed that the engine is tilted far enough back that it passenger’s side rear coil pack will collide with the heater valve making it impossible to re-install. I’d considered trying to modify the system to use an in-cabin valve like the S13 but I’d rather not do that if I don’t have to, and there are plenty of people with S14s using the external valve (sikky’s kit even has you leave it on the firewall when doing the swap)

The Fujii SPL guys had some suggestions for modifying the kit for better fitment but if it came down to that I would rather have them fabricate completely custom mounts and not use the kit I bought at all.

It’s daft innovations “new” kit with CNC mounts, and a notched S14 cross member. the header I have are daft innovations as well (cnc bent) and I’m worried how they’ll fit.

I’ve sent an email to rich and hopefully he’ll get back to me soon so I can figure out what to do next.

We’ll likely be dropping the motor out the bottom next time which I’m hoping will allow us to install the headers off of the car and make everything go much more smoothly.

If anyone has any suggestions or advice, please let me know.

the only thing that went off without a hitch were the clutch and bleeder lines.. and I spec-ed out built those myself 🙄